The successful Kobus 300 machine, used extensively by water companies and contractors in the UK, has been improved to make it even more user friendly.

Following feedback from our customers, we have introduced the following improvements to our latest models:

(a) Forward/Reverse manual control on the hydraulic power pack

In the event that users need to release tension in the pulling cable during operation, the new valve on the hydraulic power pack has the facility to be put into reverse. This avoids the problem of having to manually try to release the tension. Simple but effective!

(b) Packers on the roller assembly of the foot section

In preparation and operation, it is important that the pulling cable and extracted pipe are guided centrally around the roller assembly in the foot section to ensure they are positioned correctly onto the spool. New packers have been incorporated either side of the roller in the foot section to eliminate the issue of either the pulling cable or pipe getting snagged between the roller and frame.

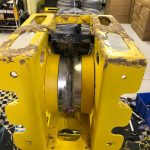

(c) Reinforced Foot Section

The lower foot section, which bears a significant amount of the pulling load, has been reinforced with 4mm section steel plate. This reduces the risk of damage to the bottom section.